Cleanroom Engineering for Semiconductor Production

- zachsievert15

- Dec 4, 2025

- 5 min read

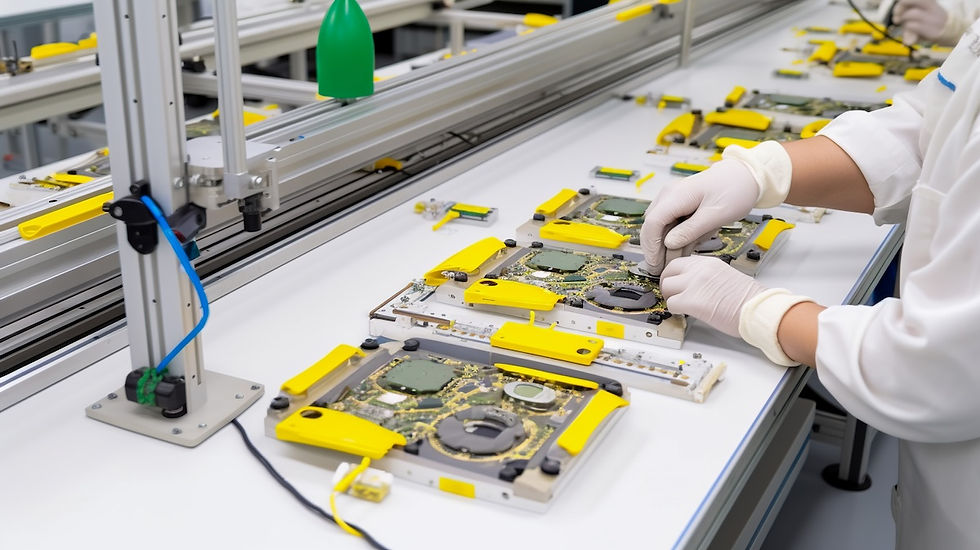

Semiconductors power nearly every part of modern life, from phones and laptops to medical devices and cars. With demand continuing to grow, achieving consistent quality and precision during production has become more important than ever. That’s why Cleanroom Engineering for Semiconductor Production plays such a central role. These clean rooms and controlled environments are designed to keep even the smallest particles from interfering with sensitive processes, and the right engineering decisions can make or break project success.

Table of Contents

Cleanroom Engineering for Semiconductor Production and Why It Matters

Semiconductor manufacturing happens at a microscopic scale where a single particle can ruin a chip or lead to defects down the line. To avoid these issues, clean room engineering focuses on creating a controlled environment where airflow, temperature, humidity, filtration, and pressure work together to protect the product.

Clean rooms in semiconductor production must meet ISO classifications that limit how many particles can exist in the air. These limits help ensure wafers stay free from contamination during lithography, deposition, etching, and packaging. Without thoughtful cleanroom engineering processes and strong construction practices, it becomes difficult to maintain these standards consistently.

Understanding Key Cleanroom Engineering Concepts

Airflow and Pressure Control

Airflow is at the heart of cleanroom engineering. Semiconductor facilities often use laminar flow systems to direct filtered air downward in a smooth, uniform pattern. This reduces turbulence and helps contaminants settle away from the work surface.

Pressure control is another essential piece. Higher pressure inside the clean room pushes air outward, keeping contaminants from entering sensitive zones. Clean room engineers design pressure cascades carefully to maintain product safety and stable environmental conditions.

Filtration and Cleanliness Levels

High-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filters are critical. These filters remove particles that cannot be seen with the naked eye, offering the clean environment required for semiconductor production.

Clean room design choices depend heavily on the ISO class required. For instance, ISO 5 spaces allow far fewer particles than ISO 7, so engineering decisions around airflow rates and filtration need to match the classification goals set for each step in the process. More detailed

Material Selection and Layout

Materials used inside a clean room must be non-shedding and easy to sanitize. Flooring, wall panels, workstations, and equipment must all minimize contamination risks. Layout planning also contributes to efficient material flow, safe personnel movement, and reduced risk of cross-contamination in semiconductor environments.

Clean Room HVAC and Environmental Control

The HVAC system is one of the most important components of any clean room build. Semiconductor processes depend on stable temperature and humidity, and even minor deviations can affect product performance or yield.

Temperature and Humidity Stability

Clean rooms typically require temperature control accuracy within narrow ranges. Humidity control is just as important, especially for electrostatic discharge-sensitive processes. An experienced clean room builder or clean room contractor will account for heat loads from equipment, lighting, and personnel to ensure stable conditions at all times.

Filtration and Air Changes Per Hour

Semiconductor facilities often require dozens to hundreds of air changes per hour depending on the clean room class. This means the entire volume of air in the space is replaced many times each hour. Clean room HVAC systems are engineered to handle this demand while maintaining energy efficiency and reliability.

Environmental Monitoring

Clean rooms rely on constant monitoring of temperature, humidity, particle levels, and pressure. Real-time systems help facility teams respond quickly to changes, preventing contamination events and protecting product consistency.

Clean Room Construction Planning

Clean room construction requires careful sequencing and strong communication between engineers, builders, and facility operators. Semiconductor projects involve strict tolerances, and oversight is essential to ensure the final clean rooms perform as designed.

Clean Room Construction Management

Construction management includes scheduling, contractor coordination, safety oversight, and documentation. Without a structured approach, it becomes difficult to deliver the performance and compliance needed for semiconductor facilities.

Clean Room Build Materials and Structure

Panels, ceilings, clean room doors, and windows must meet the correct cleanliness requirements. Smooth surfaces, airtight seals, and proper integration with HVAC systems are part of delivering a controlled environment. The clean room build also needs to accommodate electrical systems, filtration units, process tools, and wastewater management infrastructure.

Clean Room Contractor Roles

A clean room contractor plays an essential part in executing the design. From framing and panel installation to HVAC integration and finishes, each step needs precision. Semiconductor production environments cannot afford leaks, gaps, or airflow issues during operation.

Clean Room Certification and Compliance

Once construction is complete, the clean room certification stage determines whether the environment meets ISO standards and other regulatory guidelines. This step involves particle testing, airflow validation, pressure checks, and filter performance tests.

Why Clean Room Certification Matters

Certification ensures your clean room functions as intended and provides documentation required for ongoing inspections. Semiconductor manufacturers rely on accurate certification results to guarantee quality, maintain yield performance, and meet customer expectations.

Ongoing Maintenance and Recertification

Clean rooms must be maintained regularly. Filters need replacement, HVAC components must be checked, and environmental monitoring systems require calibration. Recertification is done periodically to confirm performance remains consistent.

How to Choose a Clean Room Engineer

Selecting the right clean room engineer can make a significant difference in project success. Strong engineering decisions support better product outcomes, easier maintenance, and long-term reliability.

Experience and Industry Fit

Look for cleanroom engineers with experience in semiconductor production and advanced electronics. These sectors require more precision than general manufacturing, so familiarity with ISO standards and process tool requirements is essential.

Project Capabilities

Engineers should understand clean room construction, HVAC system integration, and compliance testing. Their expertise should cover layout design, pressure mapping, clean room engineering processes, and coordination with clean room builders.

Communication and Long-Term Support

A good engineering partner stays involved from design through construction and certification. If you’re searching for guidance on how to choose a clean room engineer, prioritize companies that collaborate closely with builders, operators, and facility managers.

Cleanroom Engineering in Advanced Electronics

The semiconductor sector is just one part of the growing advanced electronics industry. Clean rooms and controlled environments support everything from microprocessors to sensors and battery components. Cleanroom Engineering in Advanced Electronics continues to evolve as products become smaller, faster, and more powerful.

For these applications, clean room engineering must stay adaptable. New materials, chemical processes, and tool requirements create ongoing demand for updated airflow solutions, HVAC improvements, and construction designs that minimize risk. Organizations like DesignTek Consulting provide engineering support for complex clean room needs, helping teams navigate design, planning, and certification more effectively.

DesignTek Consulting and Support for Semiconductor Projects

Cleanroom Engineering for Semiconductor Production depends on strong planning, precise execution, and deep industry experience. DesignTek Consulting supports services like engineering, design, and construction management for clean rooms, controlled environments, and advanced electronics facilities. Our team works closely with clients to streamline design decisions, anticipate challenges, and deliver environments that perform reliably from day one.

If you’re seeking support for semiconductor clean room projects, DesignTek Consulting can guide you through engineering, construction planning, and certification needs. Contact us to learn how our team can support your next build.

Comments